GoGetDan!

Your Team Just Got Better.

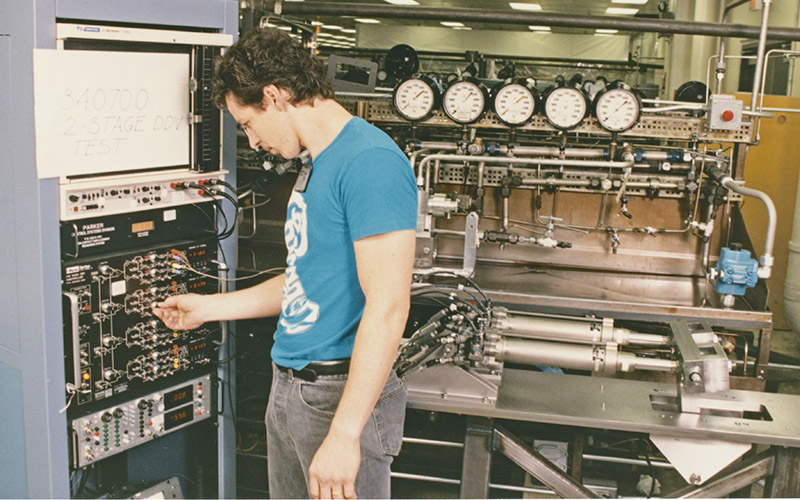

Engineering

Engineering

Manufacturing Engineers are the fundamental link between Design and Production functions. Transforming drawings into physical product and ideas into functioning workflows, there can be no doubt that a well rounded M.E. is valuable to process driven environments. Typically, they are also the first to be called upon to head up process improvement activity.

-

Knowledgable in commonly used concepts, practices and procedures in a manufacturing environment. Familiar with machining practices, fabrication and assembly techniques.

-

Experience in a production shop environment from individually machined components to complex top assemblies.

-

Understanding of a manufacturing process workflow, with ISO9000 compliant process analysis ability.

-

Planning and writing of router/traveller operations for the fabrication, test and assembly of products and tools.

-

Ability to solve practical problems, deal with a variety of variables where only limited standardization exists, while developing new, well documented procedures.

-

Read, interpret and generate free form drawings as well as controlled documentation for processes.

-

Basic to advanced mechanical design skills utilizing CAD software.

-

Demonstrated skills with the standard features of various computer word processing and spreadsheet software.

-

Excellent documentation and presentation skills.